Tagless Label Printing

Tagless Label printing Displaces Heat transfer and screen printing

Get rid of that itchy tag. Tagless printing is the fastest and least expensive ways to mark t-shirts and other apparel. It is no wonder many of the world’s leading brands are using pad printers to incorporate tagless printing over all other methods.

Whether you are using a manual HP90 or our Universal Series, the quality will be excellent with font type even as small as 6 points. Machine setup is fast and ink changeovers are painless.

Capable of printing up to 1,500 prints per hour, these units offer the ability to change images in seconds and have a simple user interface. Leading companies choose our Universal Series as their machine of choice for tagless printing.

easy setup

Our Universal Series machines are extremely easy to set up. With the ability to change images in seconds this machine is a clear winner as the entire machine can be set up directly out of the box and be ready to print in just a few minutes. All you need is compressed air and a standard electrical wall outlet to get started.

How Long Does it Take to Dry?

Print and Pack. No Drying. Seriously, that’s it. No kidding.

Our CPSIA (safe and compliant ink) is durable to at least 50 washes and lasts much longer. Print brighter white than any competitor ink with our AM-P series which has higher amounts of pigments, allowing companies to print brighter whites on darker colors without special machinery or curing.

Oh yeah, did we mention that our AM-P series ink dries on fabrics instantaneously? Just print, pack, and ship.

The proof

Tagless Label Printing

is Fast and Easy

This customer was using a competitor’s machine which was leading to frustration and repeated downtime. The solution was to switch them to our Universal 90. Now they maintain their production rate of 20,000 t-shirts per week with ease.

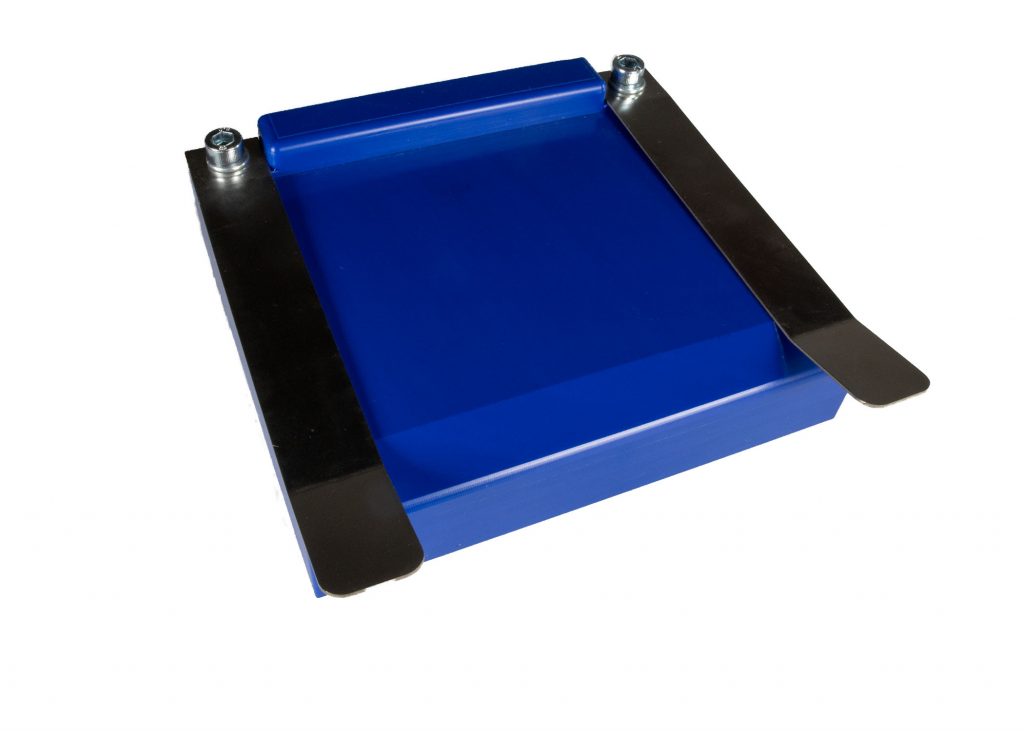

TAGLESS T-SHIRT FIXTURE

Our tagless label printing t-shirt fixture is specifically designed to allow both new and existing companies easy printing.

Two adjustable stainless steel clips allow for thin t-shirts or even thick sweatshirts to be inserted and secured under the clamps while the machine delivers the image.

The t-shirt fixture is natively attached to any of our TTN machines using the included bolts hidden under the clamps.

This fixture is made from a thermoplastic which is chemically stable and resistant to the AM-P series of ink. If AM-P ink comes in contact with the fixture, simply wipe it off. This fixture stays as good-looking year 10 as it does on day 1.

Lower Costs

Less than a penny per print with

instant drying and

super-fast print time reduces

demand on other machinery

and overall personnel.

Gain Time

Our Universal Series can run more

1,000 shirts an hour with no need

to place garments into a dryer.

Switching sizes or images is

done in seconds and new plates

with images can be made in

minutes. No machine does more!

Experience

We have outsold and displaced

other "market leaders" as the

simplicity, quality, and uptime

of our European built pad

printers surpasses the demands

of even the most exacting customers.

Quality

Our pad printed neck label will

last longer and look better than

other tagless print options. The

image won't peel, crack, or blur

leaving your brand looking great

wash after wash.